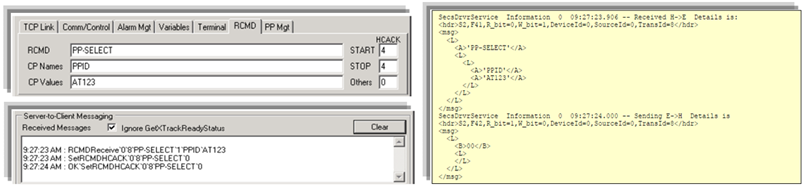

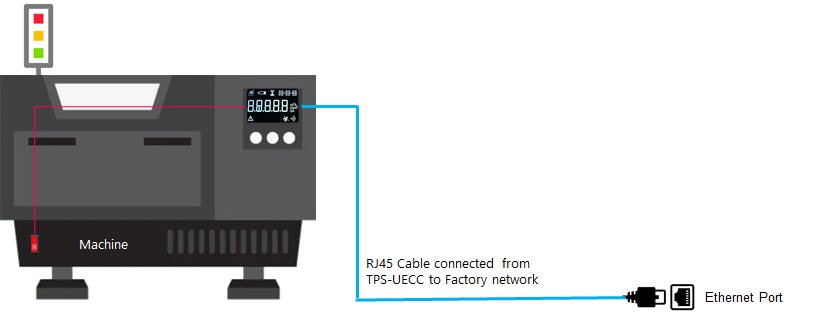

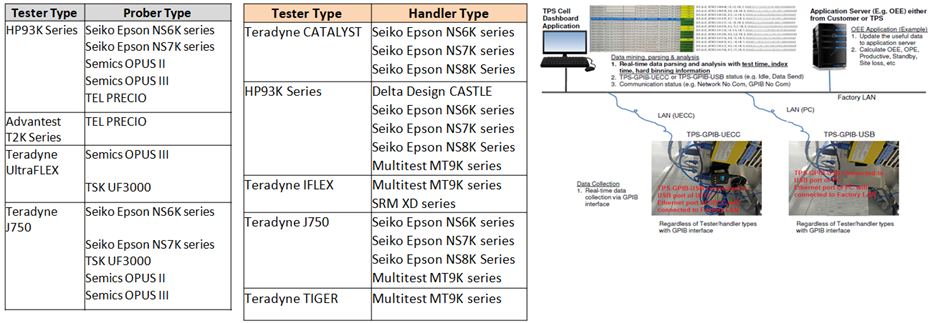

The core competency of TPS is in networking and connectivity, regardless of the age and type of equipment or devices. Proprietary interfacing techniques allow legacy equipment to be networked for controls and data acquisition.

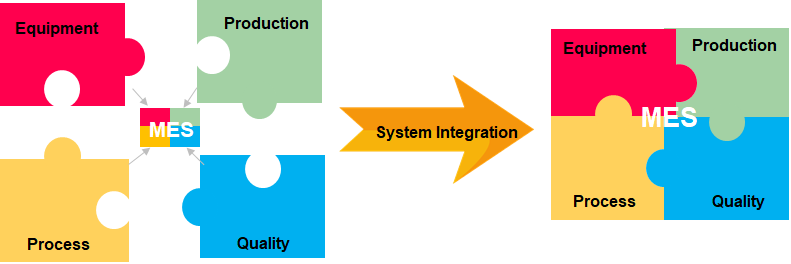

TPS has strong domain knowledge in semiconductor manufacturing process and equipment which allow us to provide cost-effective integration solutions for our customers.